OBD2, or On-Board Diagnostics II, is a standardized system that allows external devices to access diagnostic information from a vehicle’s computer. It’s essentially your car’s self-diagnostic system, providing valuable data about its performance and potential issues. This comprehensive guide will delve into what OBD2 is, its history, standards, and future trends. We’ll also explore how OBD2 data is logged and decoded, along with practical use cases.

Does My Car Support OBD2?

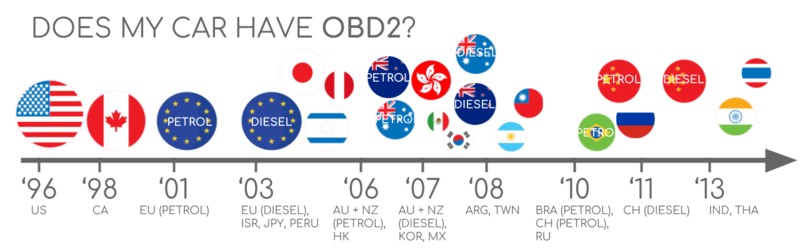

Most likely, yes. Nearly all gasoline cars sold in the US since 1996 and diesel cars sold in the EU since 2004 are OBD2 compliant. Many cars from earlier years also support the standard. A quick check under your steering wheel for a 16-pin trapezoidal connector is a good indicator. You can also refer to this handy chart:

A Brief History of OBD2

OBD2 originated in California as an emissions control initiative. The California Air Resources Board (CARB) mandated OBD systems in new cars starting in 1991. The Society of Automotive Engineers (SAE) then developed the OBD2 standard, unifying diagnostic trouble codes (DTCs) and connector types across car manufacturers. The standard was gradually adopted globally:

- 1996: Mandatory for cars and light trucks in the USA.

- 2001: Mandatory for gasoline cars in the EU.

- 2003: Mandatory for diesel cars in the EU (EOBD).

- 2008: US cars required to use ISO 15765-4 (CAN) for OBD2 communication.

OBD2 Standards: Decoding the System

OBD2 relies on several interconnected standards:

The OBD2 Connector (SAE J1962)

This standardized 16-pin connector, usually located near the steering wheel, provides access to the vehicle’s data. Pin 16 provides power, while pins 6 and 14 are typically used for CAN bus communication.

OBD2 and CAN Bus (ISO 15765-4)

Since 2008, CAN bus has been the required communication protocol for OBD2 in US cars. This standard defines specific CAN IDs for requests and responses, along with data length and bit-rate requirements.

OBD2 Diagnostic Messages (SAE J1979, ISO 15031-5)

OBD2 messages consist of modes and Parameter IDs (PIDs). Modes define the type of request (e.g., current data, DTCs), while PIDs specify the specific parameter being requested (e.g., vehicle speed, engine RPM).

The Future of OBD2

While OBD2 remains a cornerstone of vehicle diagnostics, the automotive landscape is evolving:

- Electric Vehicles: EVs often use proprietary diagnostic systems, posing challenges for standardized OBD2 access.

- OBD3: This theoretical next generation could incorporate telematics for remote diagnostics and emissions testing.

- Data Control: Concerns about data ownership and security might lead to restricted access to OBD2 data in the future.

Logging and Decoding OBD2 Data: A Practical Example

OBD2 data loggers, like the CANedge, can record data from the OBD2 connector. This data can then be decoded using software and DBC files to provide meaningful insights.

OBD2 Use Cases: Real-World Applications

OBD2 data has numerous practical applications:

- Vehicle Diagnostics: Mechanics use OBD2 scanners to identify and troubleshoot car problems.

- Fleet Management: Track vehicle location, fuel consumption, and driver behavior for optimized fleet operations.

- Insurance: Usage-based insurance programs utilize OBD2 data to assess driving risk and adjust premiums.

- Predictive Maintenance: Monitor vehicle health to anticipate potential issues and prevent breakdowns.

Conclusion

OBD2 is a powerful system that has revolutionized vehicle diagnostics and opened up a world of possibilities for data analysis and application development. While its future may evolve, OBD2’s impact on the automotive industry is undeniable. Understanding what OBD2 is and how it works empowers car owners, mechanics, and fleet managers alike to make informed decisions about vehicle maintenance and operation.