Replacing brake lines is a crucial part of vehicle maintenance, and having the right tools can make all the difference. When it comes to brake line repair directly on your vehicle, an on-car flaring tool is indispensable. This guide will delve into the best on-car flaring tools, helping you choose the perfect one for reliable and efficient brake line fixes.

Working on brake lines often requires precision and accessibility, especially when removing the entire line is impractical or time-consuming. Traditional bench-mounted flaring tools are excellent for shop work, but they lack the convenience needed for in-situ repairs. That’s where the on-car flaring tool shines, allowing you to create accurate flares without removing the brake pipe from the vehicle.

Choosing the right flaring tool is essential for safety and performance. A poorly made flare can lead to brake fluid leaks and, in critical situations, brake failure. Therefore, investing in a quality on-car flaring tool is a smart decision for both DIY enthusiasts and professional mechanics.

Types of On-Car Flaring Tools

Several types of on-car flaring tools are available, each with its own advantages and ideal applications. Understanding these types will help you narrow down your choices:

-

Handheld Flaring Tools: These are compact and designed for use in tight spaces. They typically use a screw or lever mechanism to create the flare. Handheld tools are popular for their portability and ease of use directly on the vehicle.

-

Hydraulic On-Car Flaring Tools: These tools utilize hydraulic pressure to create flares, often resulting in more consistent and effortless flaring, especially on tougher materials like steel brake lines. They can be more expensive but offer superior performance and reduce user fatigue.

-

Turret-Style On-Car Flaring Tools: Some advanced on-car flaring tools feature a turret design with multiple die sizes, allowing for quick changes between different pipe diameters without needing to swap out individual dies.

Key Considerations When Selecting an On-Car Flaring Tool

Before purchasing an on-car flaring tool, consider these important factors:

-

Ease of Use: Look for a tool that is straightforward to operate, especially in awkward positions under a vehicle. The tool should clamp securely and allow for controlled flaring.

-

Reliability and Repeatability: A good tool should produce consistent, high-quality flares every time. This is crucial for ensuring leak-free brake line connections.

-

Material Compatibility: Determine what type of brake lines you will be working with. Some tools are better suited for softer materials like copper and cupro-nickel, while others are designed for steel and stainless steel. Ensure the tool you choose is compatible with the materials you intend to flare.

-

Durability: Consider the build quality and materials of the tool. A durable tool will withstand regular use and provide a longer lifespan, justifying the investment.

-

Budget: On-car flaring tools range in price from budget-friendly to professional-grade. Determine your budget and balance it with the features and quality you require. While cheaper options exist, investing a bit more can often result in a more reliable and easier-to-use tool.

Recommended On-Car Flaring Tools Based on User Feedback

Based on discussions and user experiences, here are some recommended on-car flaring tools that stand out for their performance and value:

1. Franklin/Powerhand Type Handheld Flaring Tool:

This style of handheld flaring tool, often mentioned in user reviews, is praised for its ease of use and effectiveness, particularly on copper and cupro-nickel brake pipes. Users report success using it directly on the car. While some users found it challenging for steel pipes when used by hand, it performs well in a vice. The Franklin tool, and similar designs, are a popular choice for DIYers due to their balance of cost and capability.

Alt text: Franklin AF2003 handheld brake pipe flaring tool, suitable for on-car use and 3/16″ SAE flares.

2. Sykes-Pickavant Flaremaster 2:

The Sykes-Pickavant Flaremaster 2 is frequently cited as a gold standard in on-car flaring tools. Although a more significant investment, it is lauded for its superior performance, versatility, and ability to handle steel and stainless steel pipes with optional upgrades. Users appreciate its on-car flaring capability and the consistent, high-quality flares it produces. For professionals and serious DIYers, the Flaremaster 2 is often considered a worthwhile investment for its reliability and long-term value.

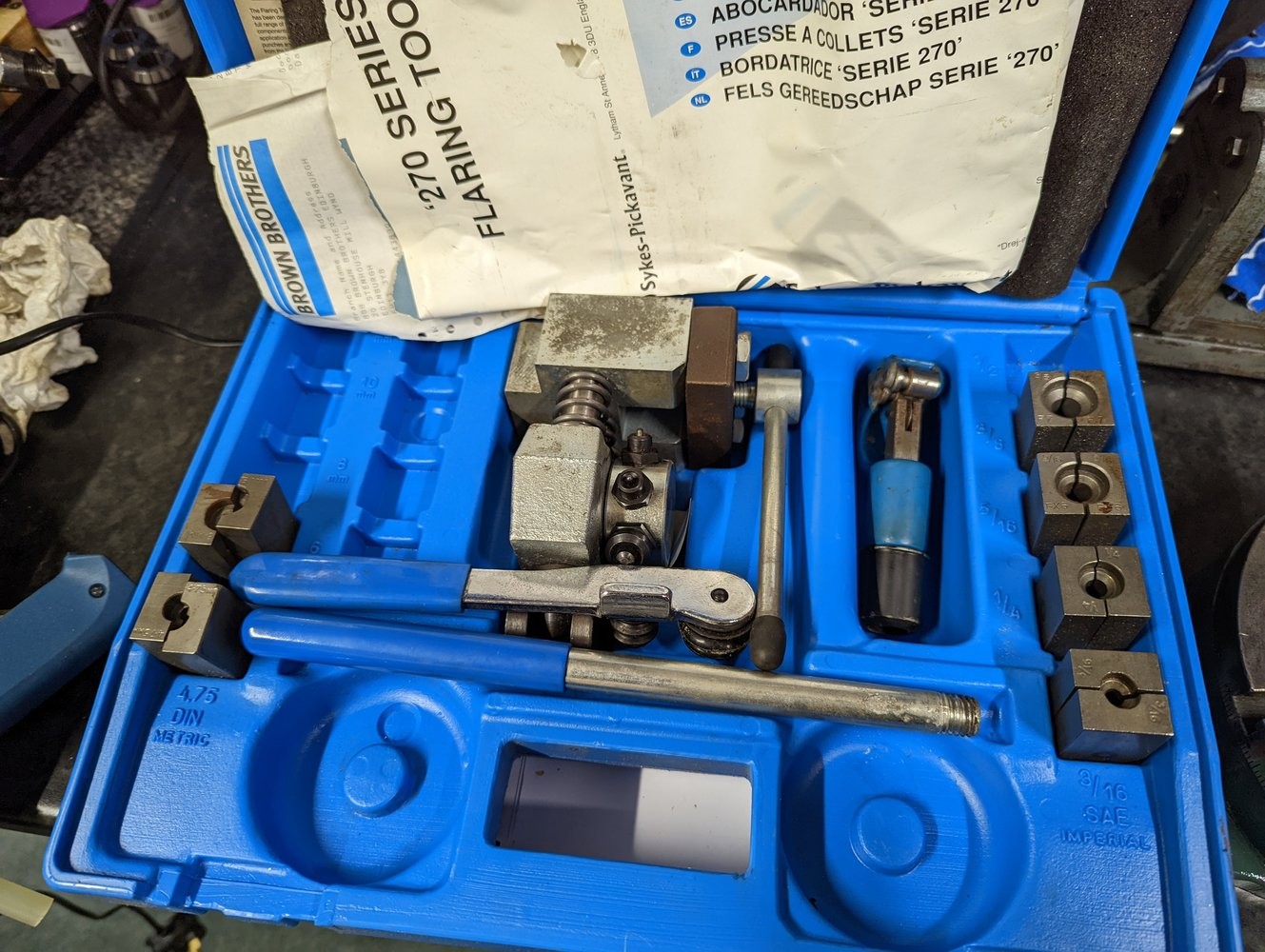

3. SP 270 Series Flaring Tool:

The SP 270 series, another offering from Sykes-Pickavant, is also recommended as a quality tool. Users suggest looking for second-hand options on platforms like eBay to potentially find it within a reasonable budget. Ensuring the tool includes the necessary imperial and metric dies is crucial when purchasing used kits.

Sykes Pickavant SP 270 Series Flaring Tool

Sykes Pickavant SP 270 Series Flaring Tool

4. Trident 413701 Brake Pipe Flaring Tool:

The Trident 413701 is mentioned as a viable option for handheld on-car flaring. It’s important to ensure you select the correct version (SAE or DIN) depending on your vehicle’s brake line fittings. This tool represents a mid-range option, potentially offering a step up in quality from basic kits while remaining more affordable than top-tier professional tools.

5. Clarke CHT229 Pipe Flaring & Cutting Kit:

The Clarke CHT229 kit, available from Machine Mart, is highlighted as a budget-friendly option that can be effective for DIY use. Users note that it may require some practice to achieve optimal flares, particularly in setting the correct pipe stick-out length. However, for occasional use on softer brake pipe materials, it can be a cost-effective solution.

Tips for Using On-Car Flaring Tools Effectively

-

Proper Pipe Preparation: Ensure the brake pipe is cut cleanly and deburred before flaring. A square and clean pipe end is essential for a good flare.

-

Correct Tool Setup: Carefully follow the tool manufacturer’s instructions for setting up the tool and clamping the brake pipe. Incorrect setup is a common cause of poor flares.

-

Practice Makes Perfect: Before working on your vehicle’s brake lines, practice making flares on scrap pieces of the same type of brake pipe. This will help you get a feel for the tool and ensure you are creating accurate flares.

-

Inspect Your Flares: After creating each flare, carefully inspect it for cracks, splits, or unevenness. A properly formed flare should be smooth and symmetrical.

-

Use the Right Fittings: Always use the correct type and size of brake line fittings for your vehicle.

Safety First

Working on brake systems is safety-critical. Always take the following precautions:

-

Brake Fluid is Corrosive: Wear appropriate personal protective equipment, including gloves and eye protection, when working with brake fluid.

-

Proper Bleeding: After replacing brake lines and making flares, thoroughly bleed the brake system to remove air and ensure proper brake function.

-

Test Thoroughly: After completing brake line repairs, test the brakes in a safe environment before driving on public roads.

Conclusion

Choosing the right on-car flaring tool is crucial for effective and safe brake line repairs. By considering the type of tool, key features, and user recommendations, you can select a tool that meets your needs and budget. Whether you opt for a budget-friendly handheld tool for occasional DIY work or invest in a professional-grade hydraulic system for frequent and demanding tasks, prioritizing quality and ease of use will ensure reliable brake line repairs and contribute to vehicle safety. Remember to practice proper technique and always prioritize safety when working on your vehicle’s braking system.