A blown fuse can bring your car to a screeching halt. While an OBD2 scanner can’t directly read a “fuse out code,” it can provide crucial clues to help pinpoint the problem. This article explores how to use an OBD2 scanner to diagnose issues related to blown fuses, understand its limitations, and guide you toward a solution.

Understanding the Role of OBD2 in Fuse Diagnostics

OBD2 scanners communicate with your car’s Engine Control Unit (ECU) to retrieve Diagnostic Trouble Codes (DTCs). These codes offer insights into various vehicle systems, including electrical components. While a specific “fuse out” code doesn’t exist, related DTCs can indicate a blown fuse. For example, if your headlights malfunction, the OBD2 scanner might display a code related to a lighting circuit failure, hinting at a potential fuse issue.

Types of OBD2 Scanners and Their Capabilities

Different OBD2 scanners offer varying levels of functionality:

Basic Code Readers:

These entry-level scanners provide basic DTC information. They might reveal electrical system faults but lack the depth for precise fuse diagnostics.

Advanced Code Readers:

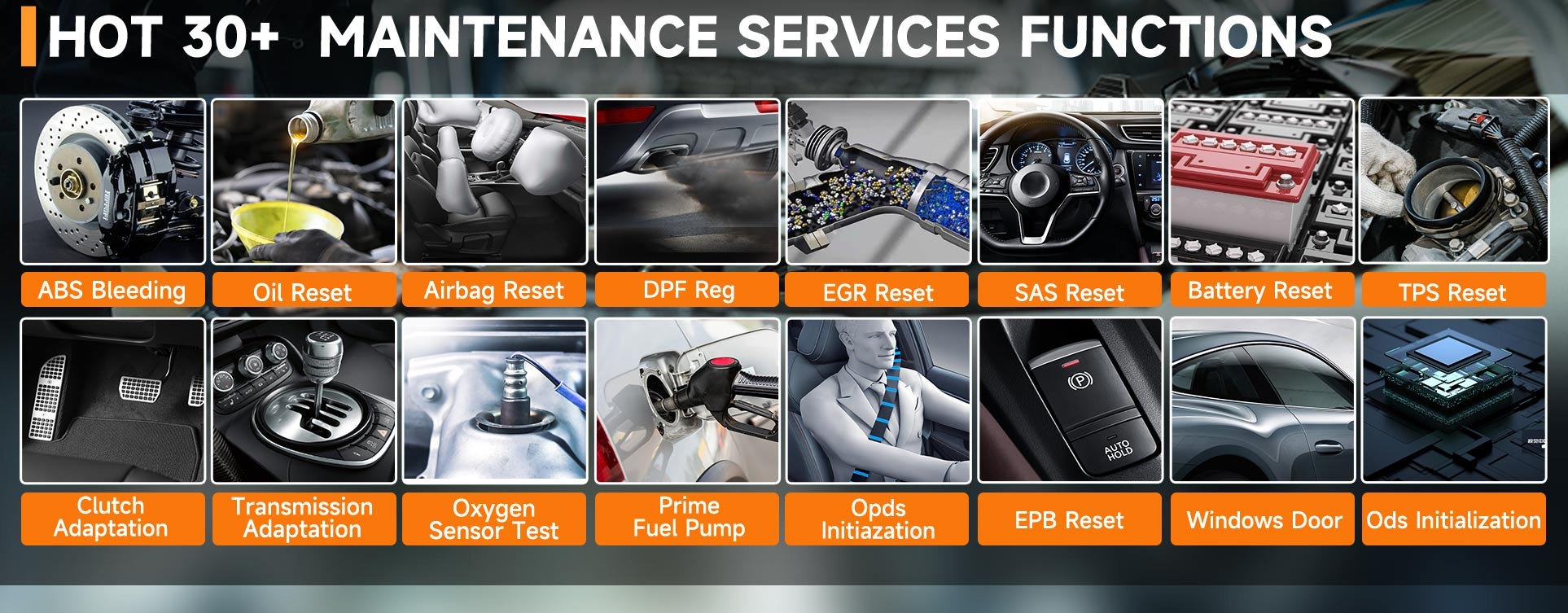

These scanners offer live data streaming, allowing you to monitor the real-time performance of electrical components. This feature can be invaluable in diagnosing intermittent issues often associated with blown fuses. The Foxwell NT809BT, for example, offers comprehensive diagnostics across multiple vehicle systems and supports live data.

Professional Scan Tools:

Utilized by experienced mechanics, these tools provide in-depth analysis, manufacturer-specific codes, and advanced functionalities for complex troubleshooting.

Using an OBD2 Scanner to Diagnose Fuse Related Issues

While an OBD2 scanner won’t directly identify a blown fuse, it can guide your diagnosis:

Look for Multiple DTCs:

Several unrelated fault codes, especially those related to electrical components, could point towards a common source, like a blown fuse affecting multiple circuits.

Analyze Live Data:

Monitor the electrical values of suspected circuits. Unusual voltage drops or erratic readings can suggest a blown fuse interrupting the flow of electricity.

Consider Communication Errors:

DTCs related to communication failures between the ECU and various modules can also indicate a blown fuse disrupting the network.

Limitations of OBD2 Scanners in Fuse Diagnostics

OBD2 scanners can’t physically inspect fuses. They rely on indirect evidence and can’t confirm a blown fuse visually. Intermittent electrical problems might not trigger consistent DTCs, making diagnosis challenging.

Conclusion

While an OBD2 scanner won’t explicitly state “fuse out,” it offers invaluable data for diagnosing related problems. By understanding how to interpret DTCs, analyze live data, and recognize the limitations of the tool, you can effectively utilize an OBD2 scanner to pinpoint the root cause of electrical issues potentially stemming from a blown fuse. Remember, a systematic approach combining OBD2 diagnostics with a visual fuse inspection is often the most effective way to resolve these problems.