Understanding OBD2 (On-board Diagnostics) codes is crucial for effective vehicle maintenance, especially for fleet management. These codes act as your vehicle’s internal communication system, alerting you to potential problems under the hood. Knowing how to interpret these “Can Obd2 Code Reader Codes” can significantly improve fleet efficiency and reduce downtime. This guide will delve into OBD2 codes, their types, how to read them, and how they can be managed effectively within a fleet.

Understanding OBD2 Code Reader Codes: Types and Meanings

OBD2 codes are alphanumeric sequences generated by your vehicle’s onboard computer system. They indicate malfunctions detected within various vehicle systems, ranging from minor issues to potentially serious problems. Each code corresponds to a specific issue, enabling mechanics or fleet managers to diagnose and address problems efficiently.

Powertrain Codes (P Codes)

These codes relate to the engine, transmission, and drivetrain. For example, code P0101 indicates a problem with the Mass Air Flow (MAF) sensor, potentially impacting fuel efficiency and engine performance.

Body Codes (B Codes)

Body codes refer to issues within the vehicle’s body systems, such as airbags, lighting, and climate control. For instance, code B0020 signifies a problem with the driver’s side airbag deployment circuit, posing a significant safety concern.

Chassis Codes (C Codes)

Chassis codes pertain to problems with the vehicle’s chassis systems, including steering, suspension, and brakes. An example is code C1234, which indicates a faulty wheel speed sensor, potentially affecting vehicle stability and braking performance.

Network Communication Codes (U Codes)

These codes highlight communication problems between the vehicle’s various modules and sensors. Code U0100, for instance, suggests a loss of communication with the Engine Control Module (ECM), often caused by a faulty battery and potentially leading to engine stalling.

Reading-OBD2-Codes

Reading-OBD2-Codes

Deciphering OBD2 Codes: Structure and Interpretation

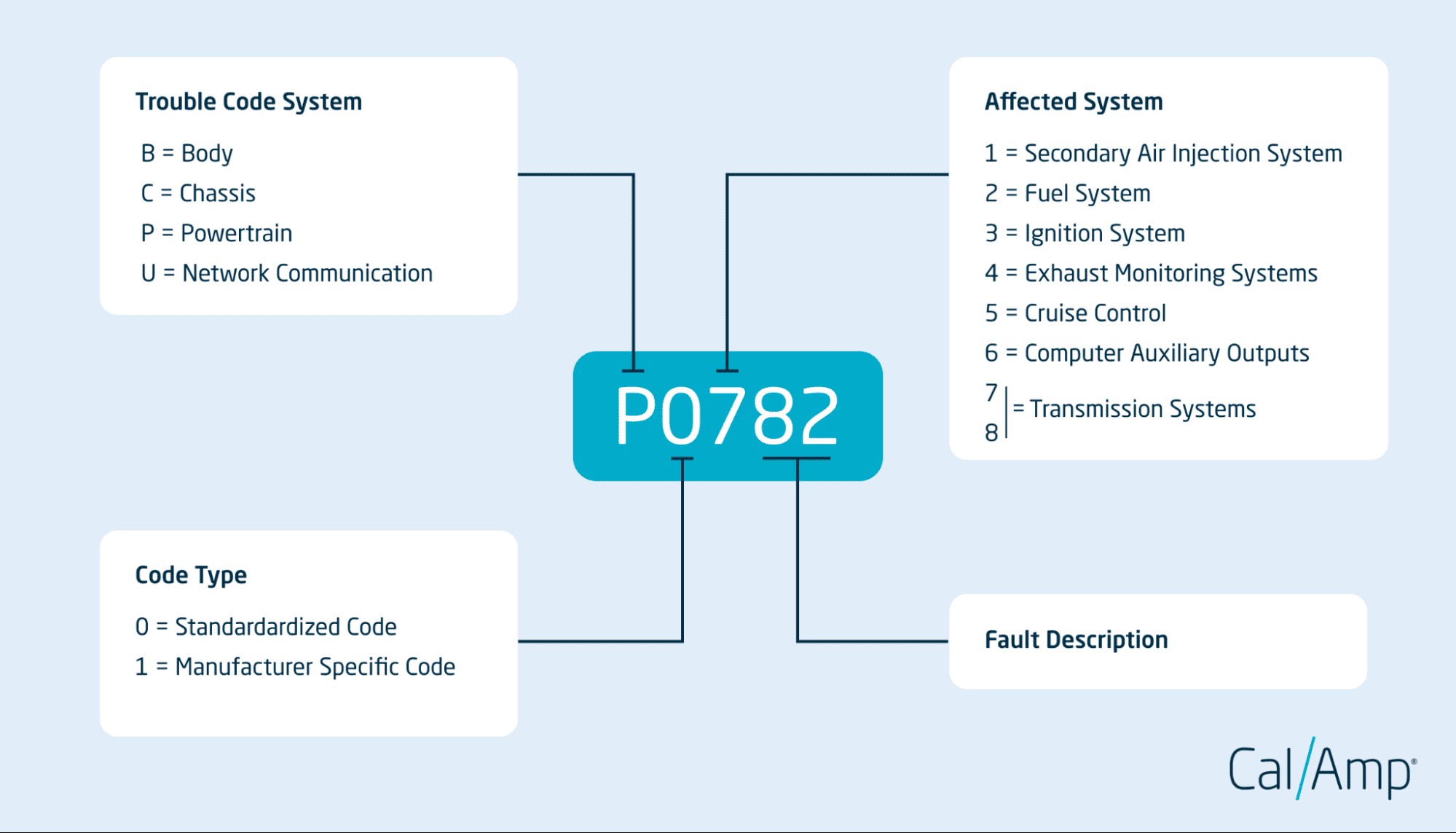

Each OBD2 code consists of a five-character alphanumeric sequence: a letter followed by four digits. Understanding this structure is key to interpreting the code’s meaning.

The first letter indicates the system related to the code: P (Powertrain), B (Body), C (Chassis), or U (Network). The first digit identifies the code type: 0 for generic (standardized across all vehicles) or 1 for manufacturer-specific. The second digit signifies the affected subsystem (e.g., fuel system, ignition system). The last two digits pinpoint the specific problem within that subsystem.

Clearing OBD2 Codes: Methods and Considerations

While clearing codes doesn’t fix the underlying problem, it’s sometimes necessary after repairs or to reset the system. This can be achieved using an OBD2 scanner, completing a specific drive cycle (if applicable), or consulting a mechanic for professional diagnosis and code clearing.

Preventing OBD2 Codes: Proactive Maintenance Strategies

Preventing OBD2 codes is crucial for long-term vehicle health and minimizing fleet downtime. Regular maintenance, including routine inspections, fluid changes, and timely repairs, is essential. Using high-quality fuel and fluids also plays a significant role in preventing issues that trigger OBD2 codes.

Managing OBD2 Codes in a Fleet: Efficient Strategies

For fleet managers, efficient OBD2 code management is paramount. Centralizing code tracking using fleet management software allows for comprehensive data analysis and proactive maintenance scheduling. Real-time fleet monitoring via telematics systems enables immediate identification of issues and prioritization of repairs based on severity.

Conclusion: Leveraging OBD2 Codes for Optimal Fleet Performance

“Can OBD2 code reader codes” are invaluable tools for understanding and managing vehicle health, especially in a fleet setting. By understanding these codes, implementing proactive maintenance strategies, and leveraging fleet management technology, businesses can significantly reduce downtime, optimize vehicle performance, and improve overall operational efficiency. Contact CalAmp today to learn more about how their fleet management solutions can streamline your OBD2 code management process.